Duotank & De Bruin Techniek: optimum tool supply for tank systems

Since 1985, Duotank has been designing, developing, manufacturing and installing beer tank systems that deliver optimal results for brewers around the world.

Challenge

Duotank strives for the perfect solution for every customer with production made to measure. Highest quality, craftsmanship and coordinated cooperation are the key to this perfection.

A tank system consists of tanks, taps and if necessary a transport solution. The entire system is thus a complete end-to-end solution. To create the perfect solution, a team of Duotank specialists with many years of experience must deliver a suitable system for each specific customer situation.

Solution

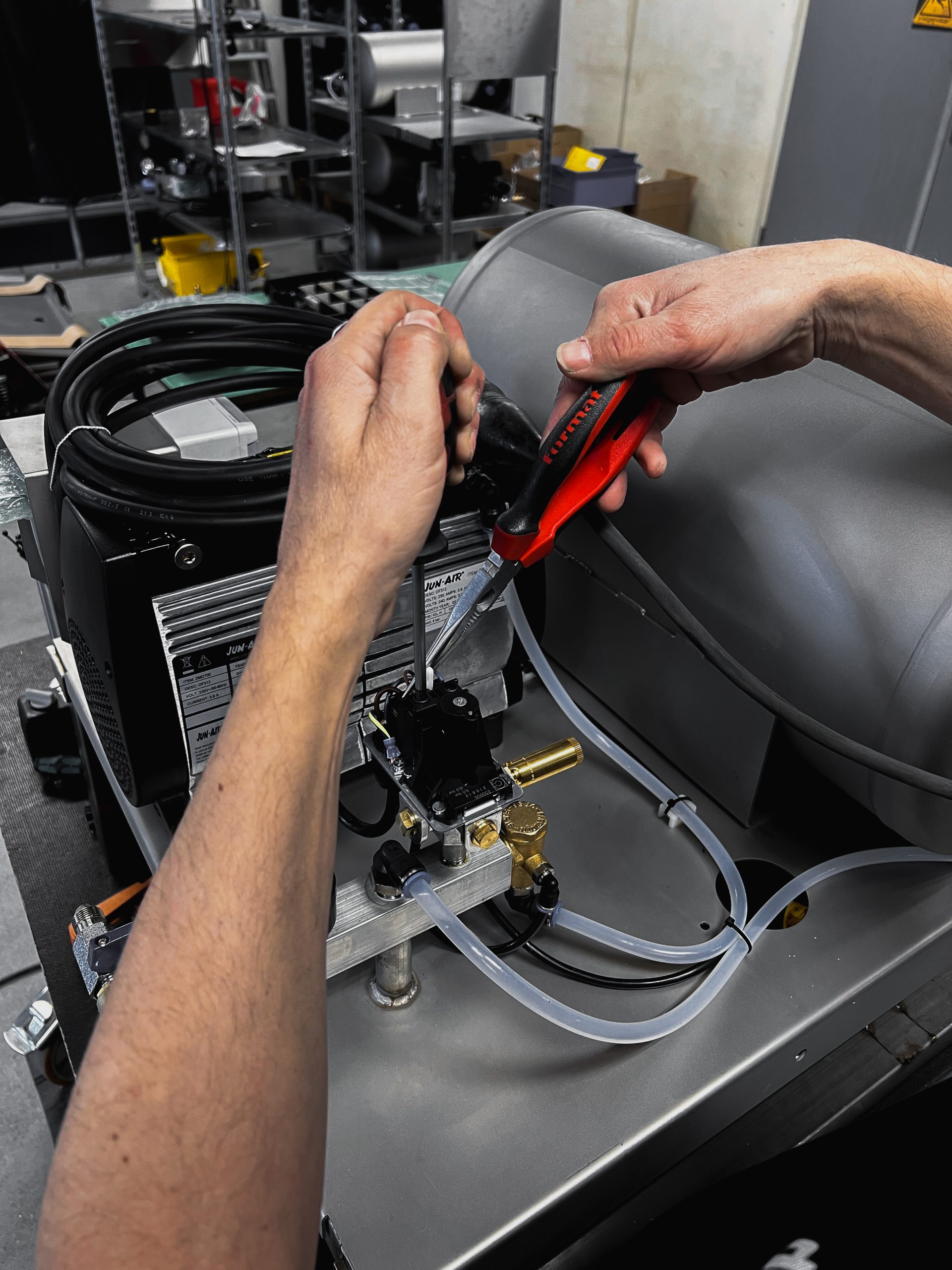

High-quality and reliable tools are essential for creating a customer specific tank system. That is why quality tools from FORMAT are used in Duotank’s production department in Waalre (Netherlands) and by the assembly teams.

For example, in order to be able to perfectly machine the air pumps, Duotank uses a FORMAT Multifunctional Pliers with a 2-component handle in 160mm. The precise drill holes on the tank, which are accurate to the millimeter, are made using the FORMAT HSSBI hole drill in 98mm.

When welding, in turn, it is important to have accurate welds so that the tank can be used for many years. To ensure this, Duotank uses FORMAT clamps. Two different types of clamps are used for this purpose. Firstly, the FORMAT glue clamp with hardened iron in 1000×120 mm and secondly, the FORMAT parallel vice in 100mm.

Benefits

Duotank receives highly functional and precise tools with the FORMAT products. In addition, the FORMAT products are always delivered directly to Duotank’s point of action within 24 hours in cooperation with the company’s long-standing trading partner De Bruin Techniek in Tilburg. This means that the tools are always in the right place at the right time – perfect delivery for a perfect tank system.